Polymers, Free Full-Text

5 (347) In stock

5 (347) In stock

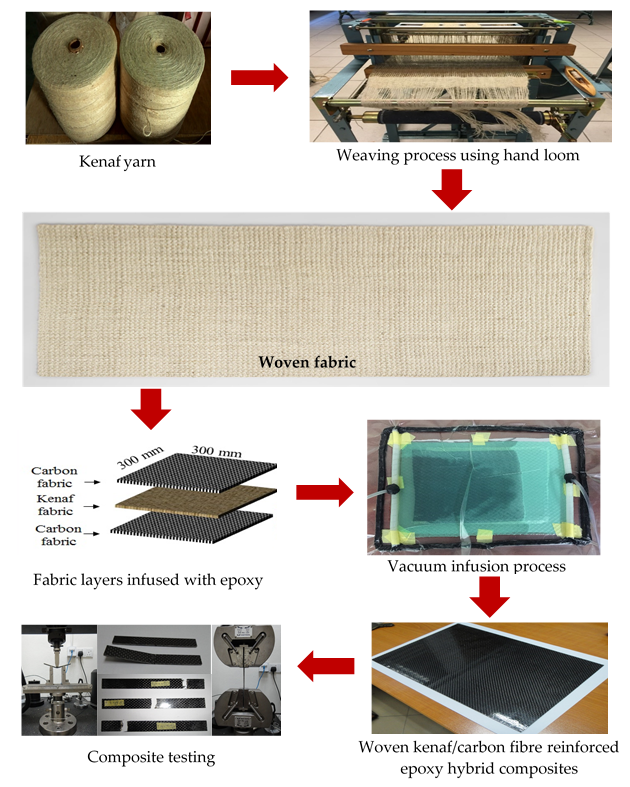

The effects of different fabric materials namely weave designs (plain and satin) and fabric counts (5 × 5 and 6 × 6) on the properties of laminated woven kenaf/carbon fibre reinforced epoxy hybrid composites were evaluated. The hybrid composites were fabricated from two types of fabric, i.e., woven kenaf that was made from a yarn of 500tex and carbon fibre, by using vacuum infusion technique and epoxy resin as matrix. The panels were tested for tensile, flexural, and impact strengths. The results have revealed that plain fabric is more suitable than satin fabric for obtaining high tensile and impact strengths. Using a fabric count of 5 × 5 has generated composites that are significantly higher in flexural modulus as compared to 6 × 6 which may be attributed to their structure and design. The scanned electron micrographs of the fractured surfaces of the composites demonstrated that plain woven fabric composites had better adhesion properties than satin woven fabric composites, as indicated by the presence of notably lower amount of fibre pull out.

Polymers, Free Full-Text, passfeder 4mm

Polymers, Free Full-Text, 3d Printer Lubricant

Polymers, Free Full-Text, pla cf

Polymers, Free Full-Text

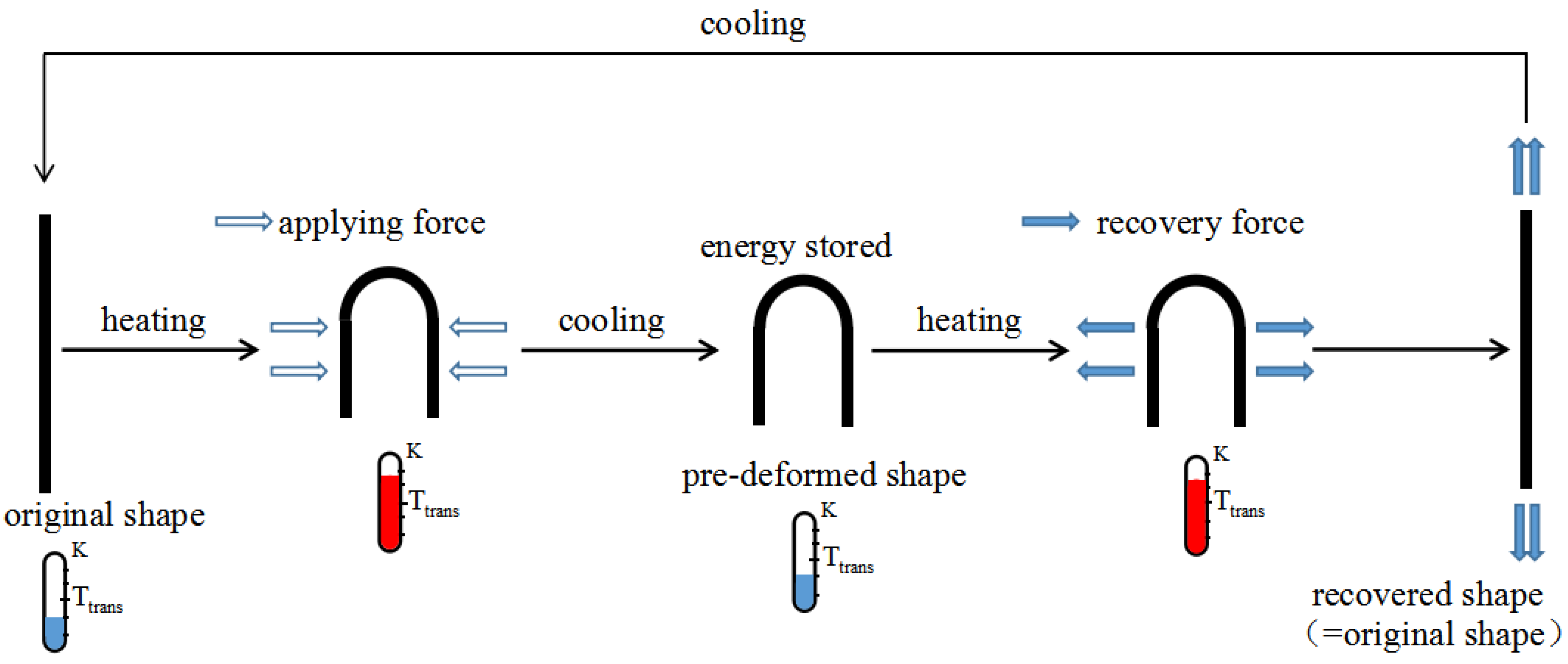

Polymers, Free Full-Text, Resin Curing

Polymers

Polymers, Free Full-Text

Polymers, Free Full-Text, códigos de double xp no block street

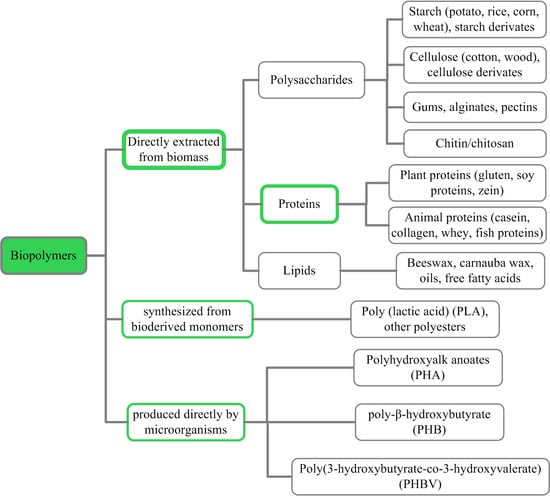

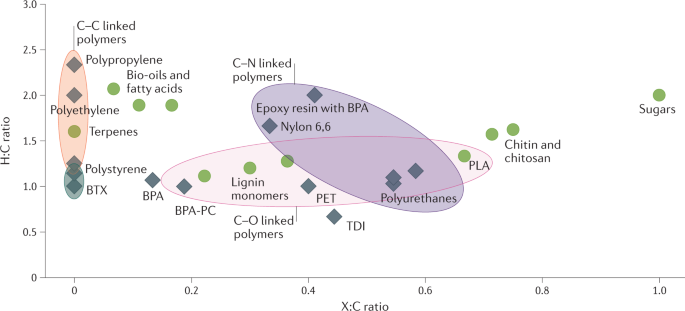

Bio-based polymers with performance-advantaged properties